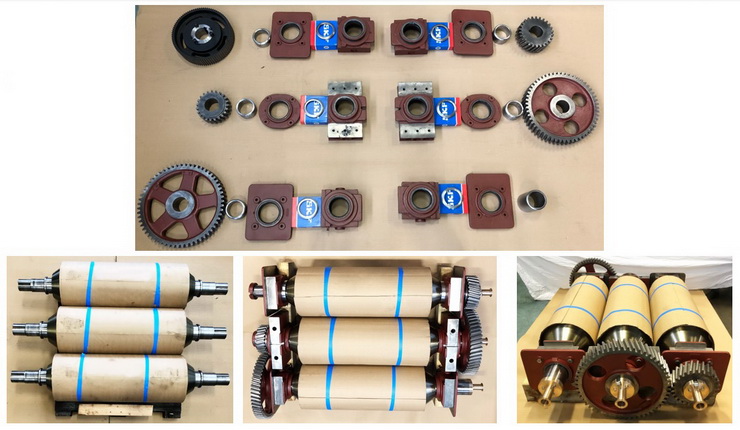

Roll Set Job (RSJ) Program for Production Three Roll Mills (TRMs)

The description as to what is included in our RSJ is given below (Items #1 to #14). Please inquire for pricing.

1) The roll set is brought into our shop and it is disassembled to parts. All parts are then inspected so that we can prepare a specific quotation. This quotation will outline the work that we intend to do, the parts (if any) that are required, and our estimate as to the charges involved. This is part of our standard charge.

2) All castings go into our heated and agitated cleaning tank, and once these are down to bare metal, these are then primed and painted. This is part of our standard charge.

3) The roll interiors are inspected to check for scaling, the interior water pipe indent is drilled out to insure proper fit, and the roll interiors are chemically cleaned. This is part of our standard charge.

4) Six (6) new bearings are supplied.

5) The bearing journals are inspected and measured for diameter. If undersize, the journal is machined, and a new journal sleeve is installed. If a sleeve is required, this is at additional charge.

6) The rolls are ground on our roll grinders. Our customers normally leave the crown specifications to our expertise. On the other hand, we can, of course, crown to customers specifications. This is part of our standard charge.

7) The roll bevels/undercuts are machined to insure that all rolls match. This is part of our standard charge.

8) The gears are topped off and recut as required to conform to the new roll centers. This is part of our standard charge. If new gears are required, these are manufactured to suit, and this is at additional charge.

9) A new set of endplates is supplied. If the existing endplates that arrive with the roll set are too small for remanufacture, then the customer is charged for a new set of endplates. Otherwise, this is part of our standard charge.

10) Twelve (12) new bearing box seals are supplied. This is part of our standard charge. If the bearing box covers have the old style felt seals, they are machined to accept the standard seals. This is at additional charge.

11) A new set of water pipes is manufactured and supplied. This is part of our standard charge.

12) The roll set is then reassembled, and after our quality assurance check, the roll set is then prepared for shipment. This is part of our standard charge.

13) When a roll set is sent into us for a RSJ, we recommend that the apron be sent into our shop also. If we do receive the apron, it is inspected to see if it needs simple service or a complete apron overhaul. The inspection is part of our standard charge. The recommended repairs, if required, are at additional charge.

14) The roll set should be sent to KMC in reusable roll boxes. If not, KMC can supply our standard reusable heavy duty roll boxes. These are at additional cost.