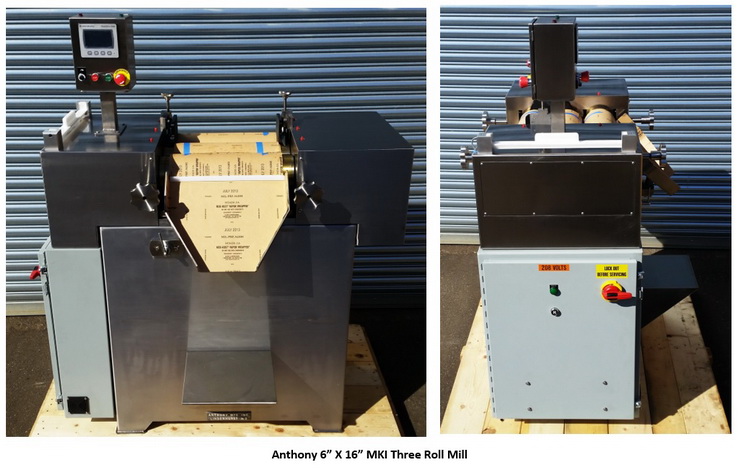

Anthony 5"x12" & 6"x14" Pilot Three Roll Mills

ANTHONY MKI PILOT THREE ROLL MILLS (TRMS) are the more basic ANTHONY TRMS (as compared to ANTHONY MKII models), and almost all of these MKI TRMS are shipped with manual roll set. These are manufactured in the following sizes: 4”X8”, 5”X12”, and 6”x14”. All ANTHONY MKI THREE ROLL MILLS (TRMS) are MADE IN THE USA, and they are standard with manual roll set, manual apron set, stainless steel frame & apron, bi-metallic centrifugally cast iron rolls, highly engineered plastic gears that require minimal lubrication, endplates that allow for mixing in the feed nip, manual roll temperature control, timing belt drive, TEFC inverter duty motor, and fully ANSI B65 / NAPIM 177.1-2017 compliant electrical package (non-explosion proof electrics, 3/60/230V or 3/60/460V) with color touch screen HMI. All of these TRMS include variable roll speed, WASH-UP MODE (A very slow speed used when cleaning the rolls), EMERGENCY BRAKING, and NGSIS (NIP Guard Safety Interlock System which insures that when cleaning the rolls, the WASH-UP STICK (in-running nip point guard) is in the feed nip, the roll nips are open, and roll speed is in WASH-UP MODE).

FEATURES

- ROLL SET – Manual roll set is standard. A normal option would be manual-electronic gap and pressure measurement system. Although MKI TRMS can also be supplied with electro-hydraulic roll set, a more logical solution would be to switch over to a MKII model.

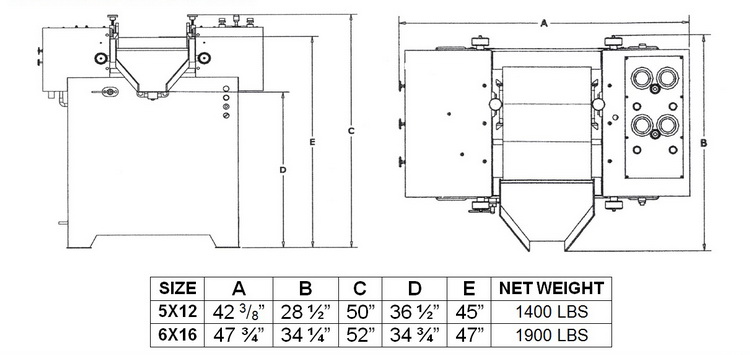

- ROLLS - Standard rolls are bi-metallic centrifugally chilled cast iron, with stainless steel rolls as an option. The rolls are made in three pieces, with two roll ends, and a roll body. The interior of the roll body is machined concentric to the roll surface to insure uniform cooling and material transfer. Roll sizes are 4” diameter x 8” long, 5”x12”, and 6”x16”.

- COOLING – Manual roll temperature control is standard, with Automatic roll temperature control as an option.

- SAFETY FEATURE - This mill is equipped with a safety system that is designed to "fail" if any foreign object passes through the rolls. This minimizes damage to the rolls and other component parts of the mill.

- FRAME - The mill frame, shoulders and side covers are constructed from stainless steel. This design makes for an excellent appearance and very easy cleanup.

- APRON - The apron is constructed of stainless steel. Positive tension of the knife against the take off roll is maintained by a counterweight system located inside the mill frame.

- ENDPLATES - This mill can be supplied with two types of endplate systems. The first system utilizes endplates that ride on the roll journals, allowing for "mixing" in the rear nip. The second system utilizes endplates that ride on the "flat of the roll". In both systems, the endplates are easily removed for cleanup.

- GEARS - Gears are made of an advanced highly engineered plastic, and the smaller pinion gears are made of steel. This combination requires minimal lubrication with grease.

- BEARINGS - The mill has anti-friction roller bearings fitted in self-aligning roll boxes.

- MOTOR & DRIVE - The rolls are driven through a quiet timing belt drive by TEFC inverter duty motor, with explosion proof motor as an option.

- ELECTRICAL PACKAGE - Is fully ANSI B177.1-2017 compliant with color touch screen HMI. Remote monitoring and data collection is an option. An explosion proof electrical package is an option.