Used (Remanufactured) Three Roll Mills

GENERAL DISCUSSION

Keith Machinery Corp. (KMC) sells and services more three roll mills (TRMs) than everyone else in North America, combined. As of January 1, 2020, KMC has more than 250 used TRMs in stock, ready for remanufacture. (View list of Used Three Roll Mills In Stock (ready for remanufacture). Brands include Buhler, Kent, Day, Lehmann, Ross, etc. Sizes available include 4” diameter x 8” long rolls, 4.5”x10”, 5”x11”, 5”x12”, 6”x14”, 8”x20”, 9”x24”, 10”x22”, 12”x48”, 13”x32”, 14”x30”, 16”x40”, and 16”x51”, etc. About 95% of the used TRMS that KMC supplies are remanufactured, with the balance being completely AS IS / AS IS TRMS (Typically sold for shipment overseas for future reconditioning), and AS IS, IN GOOD RUNNING ORDER, TESTED WITH INK TRMS (Typically sold to end users who need a quicker delivery than we can offer on a remanufactured TRM. The selling price is typically about 70% of the price of a remanufactured TRM).

All of the TRMs that KMC sells, whether new or used, are fully ANSI 2017 compliant, including variable roll speed, wash-up mode (A very slow speed that is used when cleaning the rolls), emergency braking, and NGSIS (Nip guard safety interlock system that monitors mill functions and insures that when the rolls are being cleaned, the wash-up stick (in-running nip point guard) is in the rear nip, and the mill is in wash-up mode).

The standard KMC (ANSI 2017 compliant) electrical package is NEMA 4, and it includes a color touch screen HMI mounted in the primary control station. For production size TRMs, this package includes a main electrical box, a primary control station, a secondary control station, two E-Stop stations, and a feed roll safety cable assembly. KMC normally mounts the main control box attached to the motor side of the mill frame, with everything pre-wired from that point on. This means that when a mill arrives at the branch, electrical hook-up simply consists of running a power cord to the main electrical box. If the TRM will be used in an explosion proof area, the KMC electrical package is ISXP (intrinsically safe explosion proof), and these packages can be Class 1 / Div. 2, or Class 1 / Div. 1. KMC is a UL panel shop, so all packages can be UL certified.

USED (REMANUFACTURED) TRMS

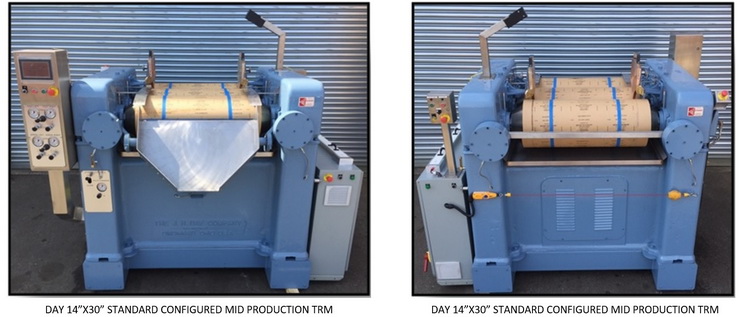

STANDARD CONFIGURED TRMS

Almost all of the used (remanufactured) Production Size TRMs that KMC now ships, are STANDARD CONFIGURED TRMs which have electro-hydraulic roll set, electro-hydraulic apron set, automatic roll temperature control, product level sensing for the feed nip, TEFC inverter heavy duty motor, quiet timing belt drive, and a fully ANSI 2017 compliant electrical package with 10” color touch screen HMI. Options for such a TRM would be a can tilter (either manual or electric), a conforming base (to raise apron discharge height), IXSP (Intrinsically Safe Explosion Proof) electrical packages, Remote Monitoring/Data Collection System, and MBAMC (Menu Base Automatic Mill Control) system, etc. Photos of a used (remanufactured) STANDARD CONFIGURED Production Size TRM are shown below. SIMPLE CONFIGURED TRMS

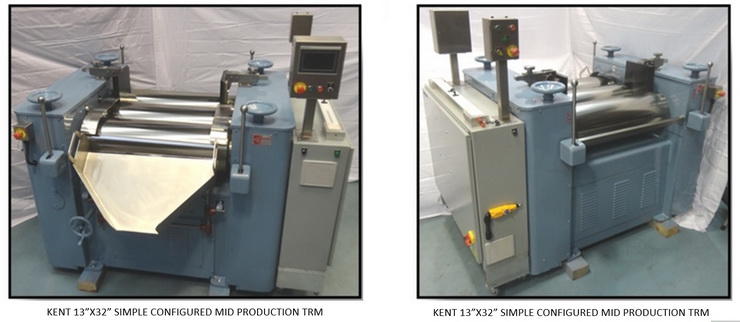

SIMPLE CONFIGURED TRMS

A very few used (remanufactured) Production Size TRMs that KMC now ships, are SIMPLE CONFIGURED TRMs which have manual roll set (manual-hydraulic roll set, or manual-load cell roll set are options), manual apron set (pneumatic apron set is an option), automatic roll temperature control, TEFC inverter duty motor, quiet timing belt drive, and a fully ANSI 2017 compliant electrical package with 10” color touch screen HMI. Options for such a TRM would be a can tilter (either manual or electric), a conforming base (to raise apron discharge height), IXSP (Intrinsically Safe Explosion Proof) electrical packages, Remote Monitoring / Data Collection System, and MBAMC (Menu Base Automatic Mill Control) system, etc. Photos of a used (remanufactured) SIMPLE CONFIGURED Production Size TRM are shown below.

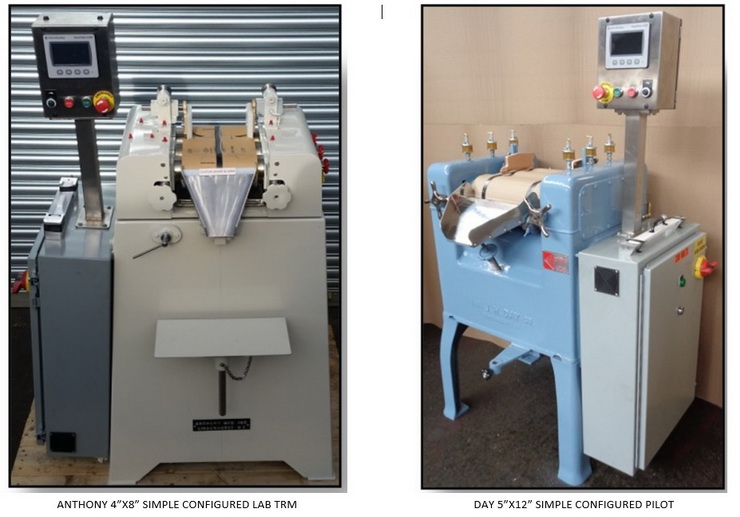

As far as used (remanufactured) Laboratory and Pilot Size TRMs are concerned, KMC now ships TRMs with a wide variety of options. These TRMs have manual roll set, (manual-hydraulic roll set, manual-load cell roll set, and electro-hydraulic roll set are options), manual apron set (manual-hydraulic apron set, pneumatic apron set, electro-hydraulic apron set are options), manual roll temperature control (automatic roll temperature control is an option), TEFC inverter duty motor, chain drive (quiet timing belt drive is an option), and a fully ANSI 2017 compliant electrical package with 7” color touch screen HMI. Options for such a TRM would be a manual can tilter, product level sensing for the feed nip, IXSP (Intrinsically Safe Explosion Proof) electrical packages, Remote Monitoring / Data Collection System, and MBAMC (Menu Base Automatic Mill Control) system, etc. Photos of a used (remanufactured) LAB & PILOT Size TRMs are shown below.

AS IS, INGOOD RUNNING ORDER, TESTED WITH INK TRMS

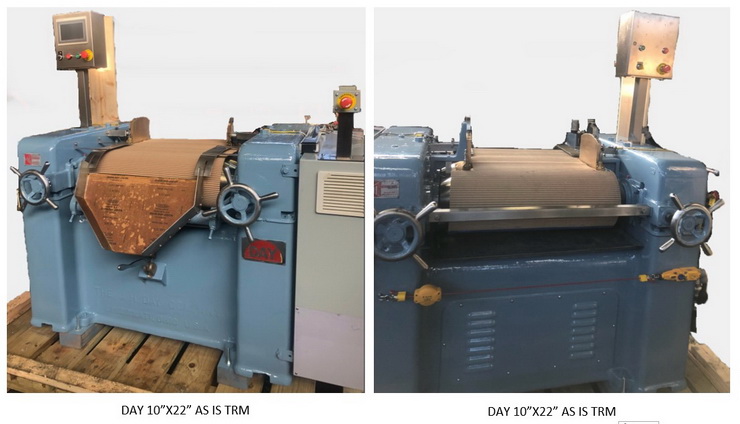

AS IS, INGOOD RUNNING ORDER, TESTED WITH INK TRMS

Less than 10% of the TRMS that KMC has in stock at any time, are candidates for this type of sale. In order to qualify, the as is roll condition must be acceptable. Typically these TRMS were running when purchased, and when such TRMS arrive at KMC, they are segregated from the general TRM population. And as time allows, these TRMS are tested with ink, to insure that they can be sold under this program. When KMC takes an order, the TRM in question is brought into the KMC shop for further testing and repairs (if required), and then a fully ANSI 2017 compliant electrical package is added. At this point, the TRM gets a final ink test, and then the TRM get cleaned, primed and painted. Photos of a typical AS IS, IN GOOD RUNNING ORDER, TESTED WITH INK TRM are shown below.