Three Roll Mills Safety

ANSI B65 / NAPIM 177.1-2017

The ANSI safety regulations (ANSI B65 / NAPIM 177.1) for three roll mills (TRMS) were extensively revised in 2007, and then reissued with some minor changes in 2017 (ANSI B65 / NAPIM 177.1 – 2017). KMC refers to these regulations as ANSI 2017, and they require that all TRMs purchased for use in the USA (after January 1, 2008) be fully ANSI 2017 compliant. To be fully ANSI 2017 compliant the TRM must have a WASHUP MODE (A very slow speed used when cleaning the rolls), EMERGENCY BRAKING, NGSIS (Nip Guard Safety Interlock System that monitors mill functions to insure that when the rolls are being cleaned, the WASHUP STICK (in-running nip point guard) is in the feed nip, and the mill is in WASHUP MODE), and a feed roll safety cable assembly (required for production size TRMs with roll length greater than 14”). The NGSIS senses the position of the feed nip and the apron nip (Whether they are open or closed), the position of the endplates (Whether they are down for running, or up for cleaning), the position of the WASHUP STICK (Whether it is in its home position, or in the feed nip), and the position of the WASHUP MODE SELECTOR SWITCH (Whether it is set for normal running, or it is set for the very slow roll speed used when cleaning the rolls). In addition, ANSI 2017 also provides a detailed procedure for the cleaning of any TRM.

Although ANSI 2017 has a GRANDFATHER CLAUSE covering used production size TRMS, that grandfather status has expired. This means that all production size TRMS that are now in operation in the USA, must be FULLY ANSI 2017 COMPLIANT, with no exceptions. Lab TRMS (roll length of 12” or less) that remain in operation, are still grandfathered, with expected full compliance being required at some point in the future. However, all new lab TRMS, and all used lab TRMS that change ownership, must also now be FULLY ANSI 2017 COMPLIANT, with no exceptions.

IT SHOULD ALSO BE NOTED HERE THAT ANSI 2017 WORKS. A TRM THAT IS FULLY ANSI 2017 COMPLIANT, IS MUCH, MUCH SAFER TO OPERATE THAN ONE THAT IS NOT. ABSOLUTELY!!!

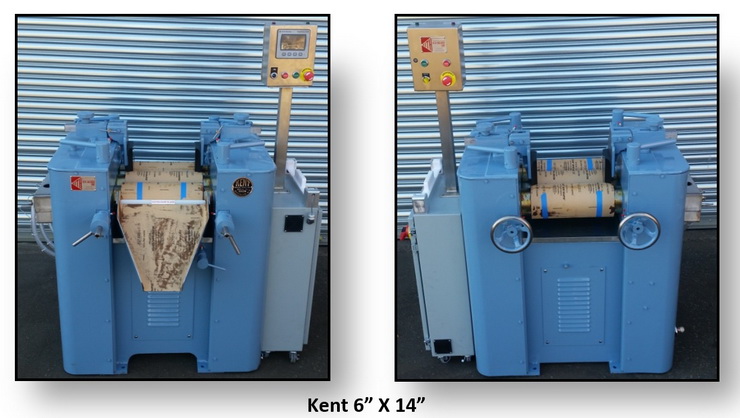

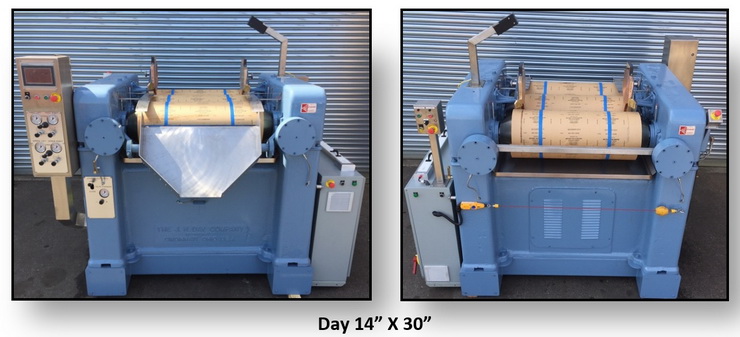

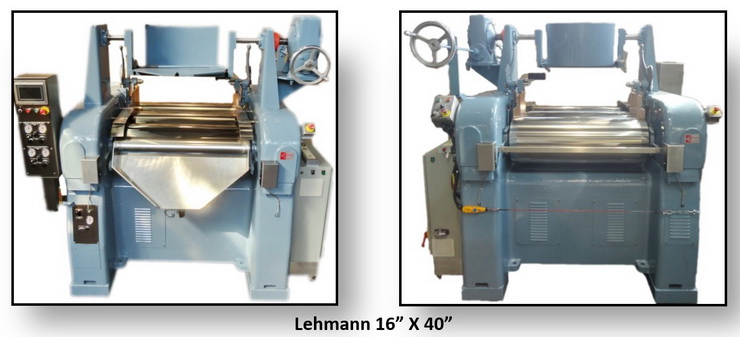

Of course, all of the TRMs that KMC supplies, whether new ANTHONY TRMs, or used (remanufactured) TRMs, are fully ANSI 2017 compliant. The following photos show the KMC standard fully ANSI 2017 compliant electrical package installed on a new ANTHONY MKII 6”x8” TRM, installed on used (remanufactured) KENT 6”x14” TRM, installed on a used (remanufactured) DAY 14”x30” TRM, and installed on a used (remanufactured) LEHMANN 16”X40” TRM. As can been seen in these photos, KMC typically attaches the main electrical box to the mill frame (motor side), with everything pre-wired from there. Electrical hook up is then just a matter of bringing power to the main electrical box.

KMC OPERATION / SAFETY CLASSES FOR THREE ROLL MILLS

KMC OPERATION / SAFETY CLASSES FOR THREE ROLL MILLS

KMC believes that after ensuring that a TRM is fully ANSI 2017 compliant, the most important single item that a company can do to avoid accidents, is to provide regular training classes. Operators need to be constantly reminded that a TRM can “bite” them. KMC recommends that a full TRM OPERATIONS / SAFETY CLASS be scheduled once each year, with shorter in-house classes being scheduled on a quarterly basis. Further, KMC believes that using an outside contractor to run this yearly class, adds to the its importance in the operator’s mind.

Although the KMC class can be tailored to the client’s specific needs, our standard instruction covers both good operating procedures, as well as all safety items. Normally, this is not just a classroom exercise. The instructor brings the class out onto the mill floor, beginning with a “clean/cold" mill, running the customer’s product, and then demonstrating how to clean the mill at the end of the run. (Note: This cleaning procedure will be according to ANSI 2017). Finally, KMC can issue a certificate to all operators who attend the class.

Finally, TRM safety is something that KMC is fully committed to. KMC knows about TRMs from the ground up, and our goal is to eliminate mill accidents. KMC charges an hourly rate (portal to portal) plus mileage and expenses. In 2020 this rate is $200/hr. What follows is the outline that the KMC instructor will follow during his class.

OUTLINE FOR KMC OPERATIONS / SAFETY CLASS

1) General discussion of Three Roll Mill Safety

A. What do the ANSI safety regulations require (ANSI B65/NAPIM 177.1-2017)

B. Discussion of the two (2) main dangers

1. Cleaning the feed roll and the in running (rear) nip

2. Installing and removing the apron knife

2) Set up of a clean mill, prior to running

A. General lubrication... When to lubricate, how often to lubricate, where to lubricate, what grease and oil to use

B. Check that the oil level indicators show correct oil level in gear reservoirs

C. Check that cooling water is off

1. Discussion concerning the inlet water solenoid valve

D. Check of apron

2. Condition of slot for apron knife

3. Installation of new knife

4. How to check condition of used knife and when it should be discarded

5. Alignment of apron on apron roll

E. Condition, alignment and tension of silent chain drive. Discussion of timing belt replacement

F. Condition and positioning of endplates

3) Mill start up, Balancing and Heating Phase

A. Step by step discussion of how to properly start up the TRM

1. Use of the WASHUP MODE

2. Correct procedure to close the feed nip and the addition of product to be milled

3. Correct procedure to balance the TRM

4. Discussion of procedures for a TRM with an automatic roll temperature control system, and also for a TRM with a manual water cooling system

B. When to put the TRM into high speed

1. What to expect from the low speed to higher speed transition

2. How to "read" the flow of ink off the apron

4) Running Phase

A. The end plate check and migration tendencies

B. The apron check and knife end considerations

C. Wetting out of a product. When are multiple passes called for? What to do about "leave back" or "tailings" in the feed nip?

D. At what point should the mill be stopped? Discussion of running dry and "tearing" the rolls.

E. Product level sensing for the feed nip.

5) Cleaning Phase

A. Use of the emergency stop button

B. Step by step procedure for cleaning the mill

1. The correct "order of cleaning"

2. Cleaning the feed roll. Discussion of the "wash up stick" or "nip point guard". Discussion of the "rear roll safety bar".

a. Correct cleaning procedure

b. Enactment of the most common accident known as "saving the cleaning rag". How to avoid this.

3. When to disengage the apron from the apron roll. How to do this correctly.

a. How to remove and discard the apron knife safely

b. Discussion of apron knife guards and other procedures

c. Correct cleaning procedures for the apron, itself.

4. Cleaning the apron and center rolls

5. Cleaning the endplates

6. Re-setting the mill for the next batch

6) Discussion of General Mill Theory/Operation of the mill as loose as possible, consistent with the product desired". What does this mean, practically?

7) Systems that can be added to TRM

A. Safety Systems

1. The "wash-up mode"/ Increased reaction time in the cleaning phase (required by ANSI 2017)

2. Emergency braking (required by ANSI 2017)

3. NGSIS (Nip Guard Safety Interlock System (required by ANSI 2017)

4. Manual wash-up system, with true electric power lock off

5. Knee safety trip wire (feed side)

6. Overhead safety trip wire (or wire around top of mill)

B. Product Repeatability Systems

1. Manual hydraulic roll set, manual-load cell roll set, & electro-hydraulic roll set

2. Mechanical gapping system

3. Electro-hydraulic apron set, manual hydraulic apron set, & pneumatic apron set

4. Automatic roll temperature control system

5. Roll speed control (the VFD)

C. Mill Feeding Controls

1. Product level sensing device for feed nip

2. Can tilter

3. Feed Pumps

4. Press out units

8) Review of Safety Items

9) Question and Answer Period

10) Written test (Optional)

11) Issuing of Certificates

KMC Three Roll Mill Safety Class / Instruction Class

It is our opinion that, by far, the most important single item that a company can do to avoid accidents, is to provide regular training classes. Operators need to be constantly reminded that a Three Roll Mill can “bite” them.

A KMC instructor could visit your facility once each year to conduct such a training class. The class would also cover good operating procedures, as well as all safety items. Normally, this is not just a classroom exercise. The instructor brings the class out onto the mill floor, beginning with a “clean/cold" mill, running the customer’s product, and then demonstrating how to clean the mill at the end of the run. (Note: Your facility and KMC to agree as to what will be your facilities “standard cleaning procedure”, so that all operators get the same instructions). Finally, KMC can issue a certificate to all operators who attend the class.

We believe that using an outside contractor to run these classes, adds to their importance in the mill operator’s mind. We also recommend conducting a safety class at least once each quarter, with three of the classes/discussions being done in house.

Finally, mill safety is something that we are fully committed to. KMC knows about Three Roll Mills from the ground up and we want to reduce mill accidents. KMC charges an hourly rate of $110/hr. What follows is the outline that the KMC instructor will follow during his class.

Outline For KMC Three Roll Mill Safety / Instruction Classes

1) General discussion of Three Roll Mill Safety

A. What do the ANSI safety regs say

B. Discussion of the 2 main dangers

1.Cleaning the feed roll and the in running (rear) nip

2.The apron knife

3.Using the electrical prewire system to enhance safety

4.Use of the "E" stop buttons

2) Set up of a clean mill, prior to running

A. General lubrication... When to lubricate, how often to lubricate, where to lubricate, what grease and oil to use

B. Check that the 2 oil level indicators show correct oil level in gear reservoirs

C. Check that cooling water is off

1.Discussion on water solenoid valve

D. Check of apron

1.Condition of slot for apron knife

2.Installation of new Knife

3.How to check condition of used Knife

4.Alignment of apron on apron roll

E. Condition, alignment and tension of silent chain drive. Discussion of timing belt replacement

F. Condition and positioning of endplates

3) Mill start up, Balancing and Heating Phase

A. Step by step discussion of how to properly start up and mill

1.Use of low speed

2.Correct procedure to close rear nip and the addition of product to be milled

3.Correct procedure to balance the mill

4.When to bring on cooling water and discussion of water cooling system

B. When to put mill into high speed

1.What to expect from the low speed to high speed transition

2.How to "read" the flow of ink off the apron

4) Running Phase

A. The end plate check and migration tendencies

B. The apron check and knife end considerations

C. Wetting out of a product. When are multiple passes called for. What to do about "leave back" or "tailings" in rear nip.

D. At what point should the mill be stopped? Discussion of running dry and "tearing" the rolls

5) Cleaning Phase

A. Use of the emergency stop button (electrical lockout/sort of)

B. Step by step procedure for cleaning the mill

1.The correct "order of cleaning"

2.Cleaning the feed roll. Discussion of the "wash up stick" or "nip point guard". Discussion of the "rear roll safety bar".

a. Correct cleaning procedure

b. Enactment of the most common accident know as "saving the cleaning rag". How to avoid this.

3.When to disengage the apron from the apron roll. How to do this correctly.

a. How to clean the apron knife. Do you really want to clean the apron knife. A discussion.

b. Discussion of apron knife guards and other procedures

c. Correct cleaning procedures for the apron, itself.

4.Cleaning the apron and center rolls

5.Cleaning the endplates

6.Re setting the mill for the next batch

6) Discussion of General Mill Theory/ "Operation of the mill as loose as possible, consistent with the product desired". What does this mean, practically.

7) Systems that can be added to Three Roll Mill

A. Safety Systems

1.The "wash-up mode"/ Increased reaction time in the cleaning phase

2.Emergency braking

3.Manual wash-up system, with true electric power lock off

4.Always in nip point guard

5.Knee safety trip wire (feed side)

6.Overhead safety trip wire (or wire around top of mill)

B. Product Repeatability Systems

1.Electrohydraulic roll pressure system

2.Electrohydraulic apron knife pressure system

3.Roll temperature control systems

4.Roll Speed control (the VFD)

C. Mill Feeding Controls

1.Product level sonar device

2.Can tilter

3.Feed Pumps

4.Press out units

8) Review of Safety items

9) Question and Answer period

10) Written test (Optional)

11) Issuing of Certificates