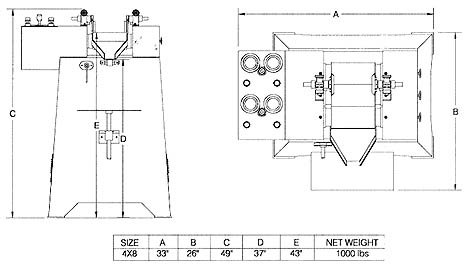

Anthony 4" x 8" Laboratory Three Roll Mill

- Steel or Stainless Rolls

- Four Point Adjustment

- Quick Release Feature

- Hydraulic Pressure Units (Optional)

- Bronze or Teflon Endplates

- Water Cooled Rolls

- Roller Bearings

- Spiral Gears

Features:

Rolls - The rolls are 4" diameter by 8" long on the grinding surface. The inside of the roll is machined concentric to the roll surface to insure uniform cooling and material transfer. Standard rolls are constructed of hardened steel. Options can be stainless steel rolls, ceramic coated rolls, tungsten carbide coated rolls, etc.

Cooling - All three rolls are water cooled with individual valves to control the flow of water. A cast bronze water manifold and a cast iron water box is standard. Mills can also be equipped with automatic temperature control systems.

Adjustment - The mill has four point handwheel adjustment (two handwheels for the feed roll and two for the apron roll). Each handwheel has a locknut for locking the hand-wheels in place. Options are manual hydraulic roll set and electrohydraulic roll set.

Quick Release - The apron and feel roll can be opened without turning the handwheels. The quick release feature on the mill works as follows:

Moving the handwheels away from the center of the mill allows the apron and feed rolls to separate from the fixed center roll. Moving the handwheels back toward the center of the mill brings the roll back into contact with the fixed center roll, duplicating the previous setting. Rolls can be opened and closed repeatedly without affecting the setting. Mills with manual hydraulic roll set and electrohydraulic roll set also have this quick release system.

Safety Feature - The four handwheels are fitted with safety shear pins. These pins will shear if any foreign object passes through the rolls. This prevents damage to the rolls or other component parts of the mill. Mills with manual hydraulic roll set also have sheer pins. Mills with electrohydraulic roll set have a dump system to release overpressure.

Frame - Construction is of two parts. The roll boxes are mounted on a heavy, cast iron base. This base is precision machined to insure perfect roll alignment. This base is spring mounted to a structural steel (stainless steel is an option) pedestal cabinet of modern design. This pedestal cabinet has a lower storage shelf in the back, and the motor is mounted on the upper shelf.

Lubrication - All bearings and gears have individual lubrication fittings.

Apron - The apron is constructed of machined steel (stainless steel is an option). Positive tension of the knife against the takeoff roll is maintained by a weight located inside the pedestal cabinet. This tension is adjustable. By turning the apron lever, the tension on the apron is released and the apron can be removed for cleaning.

Blade - The apron blade (or knife) is thin (.015") and flexible. It can be removed without the use of tools. The standard knife is constructed of spring steel with a single bevel (stainless steel is an option).

End plates - The end plates are designed not to bear on the rolls, and they are adjustable to control the spread of material across the grinding surface of the rolls. They can be raised or removed for cleaning. The end plates are constructed of bronze (teflon is an option). Buhler type endplates which allow for mixing on the rear two rolls is an option.

Gears - The machine is supplied with spiral cut cast iron gears and steel pinions. This gear train has been designed for smooth and quiet operation.

Bearings - The mill has anti-friction roller bearings fitted in self aligning roll boxes. These boxes are designed to prevent the entrance of foreign matter.

Motor & Drive - The standard motor supplied with the mill is a single speed, 1HP dual voltage, TEFC, three phase motor. Options include brake motors, single phase motors, explosion proof motors, variable speed motors, etc. The front roll is driven through a quiet timing belt drive.

Can Shelf - The mill is supplied with a can shelf mounted on the front of the pedestal cabinet. The height of the shelf under the apron is adjustable to accommodate various size containers.

Manual Hydraulic Roll Set - Hydraulic pressure units are available as optional equipment. These units are installed at each point of adjustment. Two on the front roll and two on the back roll. They accurately record pressure required for specific grinds of materials. Duplications of grinds are quick and positive. Units are designed with safety shear pins to prevent damage to pressure gauge should any foreign object pass through rolls. When necessary to add hydraulic fluid, unscrewing hand wheel off unit gives access to filler fitting for which a hydraulic gun is furnished. Each unit is equipped with a bleeder valve for removal of excess fluid and air. Note: A mill supplied with these hydraulic pressure units retains the quick release system.