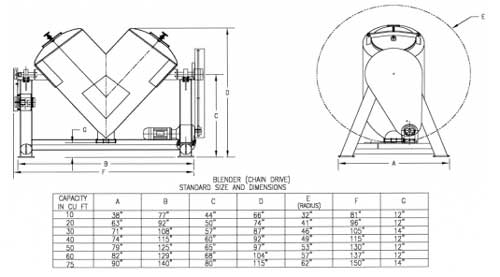

"Vee" Blender (10 cubic foot & larger)

- 316 SS Contact Parts

- Mild Steel Painted Support Stands. Stainless Steel optional.

- White Neoprene for Contact Gaskets

- Internal Finish: 30-35 Microinch, All Welds Ground Smooth & Flush

- (Higher Surface Finishes upon request)

- External Finish: #4 with Welds Color Cleaned

- Butterfly Discharge Valve and Clamp Type Charge Covers

- SS Stiffener Plates

- Blenders can be ordered with various control packages. All are standard with Nema 4 stainless Steel Enclosures.

- Blenders can be ordered without intenfisier, or with Pin Type Bar, High Speed Solid Bar, or Liquid-Solids Bar

- Chain Drive is standard; gear drives supplied 100 cubic foot and larger.

- Shell Construction - KMMC blenders are standard with type 316 stainless steel contact parts, although type 304 stainless steel or other metals can also be used. In pharmaceutical use, stiffener plates are also stainless steel.

- Discharge Valve - KMMC blenders are standard with butterfly discharge valves. The diameter of the valve depends on the size of the blender. The butterfly is constructed of type 316 stainless steel, while the valve body and valve handle are constructed of aluminum. The standard valve has white neoprene internals. Options include a valve with stainless steel body and valve, or a tri-clamp outlet with easy disassembly/cleanup butterfly valve (Cora type).

- Charge Ports - KMMC blenders are standard with charge flanges machined for "o" rings, and KMMC designed covers and hold down bars.

- Blender Stands - KMMC blenders are standard with stands fabricated from tubular steel. These stands are normally painted with two-part epoxy paint, or with stainless steel paint. Stainless steel stands are an option. Blender stands are constructed with a permanent rear stabilizing cross bar, as well as a removable front cross bar.

- Surface Finish - Shell interiors (contact parts) are standard with a #4 (30 to 35 RA/micro inch) finish. Other, more highly polished finishes are options, up to a "Mirror Finish". Shell exteriors are buff. Internal and External Shell electropolish available including passivation upon request.

- Control Packages - KMMC blenders are quoted as standard with optional control packages. Control packages include Nema 4 stainless steel with push buttons, timer, control transformer, and motor starter with overload heaters. Timer controls length of shell rotation, digital type timer, controls self contained and supplied loose unless directed, shell positioner available at additional charge. Bar & liquid control packages include 3 timers for shell, bar, and pre-blend time prior to bar use, additional cost for bar package. However, KMMC also offers upgraded control packages which includes a VFD for soft starting and stopping, a stop system that always stops the blender with the discharge valve in the down position, and a lock out system that insures that the blender can not operate unless all safety systems are properly set. The blender can be offered as "pre-wired" as an option. Other options include explosion proof motors and intrinsically safe explosion proof pre-wires, etc. Can be offered with controls mounted and prewired as an option.

- Shipping Bar - The base of all blenders, 5 cu ft and larger are fabricated with a removable "shipping bar". This bar is designed so that the blender is easily forkliftable for both transport and putting the blender into position, and lifting the blender so that it can be put onto a fabricated base (by KMMC) or onto concrete piers (by customer). Once the blender installation is complete, the "shipping bar" can be unbolted and stored away.

- Note - Smaller and larger sizes available utilizing different transmissions configuration as standard. Please inquire.